Cycloidal reducer is a new type of transmission machinery which adopts planetary transmission principle with small tooth difference and cycloidal gear combination. It is widely used in driving and reducing devices in textile printing and dyeing, light industry food, metallurgical miners, petrochemical industry, lifting transportation and engineering machinery.

Feature:

● Smooth running,low noise gear tooth needle more engagement.

● Cycloidal tooth profile provides a high contact ratio to withstand overload shocks

● Compact size: single ratio available from 1/9 to 1/87, double stage up from 1/99 to 1/7569

● Ideal for dynamic applications: frequent start-stop-reversing duties suits for cyclo speed reducer since inertia is low

● Low maintenance costs ,high reliability, long service life, minimal maintenance compared to conventional gearboxes

● Grease Lubricated & Oil Lubricated Models Available

● Output Shaft Rotation Direction: Single Reduction: Clockwise Rotation; Double Reduction→ Counter Clockwise Rotation

● Cycloid reducer Capacity Range: 0.37kW ~ 11kW;

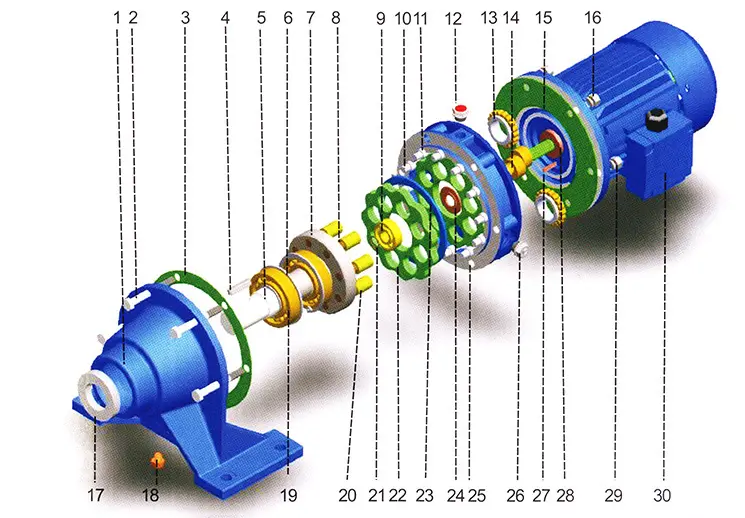

Details of the reducer

1 | Base | 16 | Nut |

2 | Hexagon bolt | 17 | Oil seal |

3 | Base gasket | 18 | Hexagon bolt |

4 | Flat key | 19 | Bearing |

5 | Circlip | 20 | Roller |

6 | Circlip | 21 | Clrclip |

7 | Output shaft | 22 | Cycloid gear |

8 | Pin | 23 | Patition ring |

9 | Bearing | 24 | Eccentric shaft knots |

10 | Gear pin | 25 | Pin wheel housing |

11 | Gear roller | 26 | Oil level plug |

12 | Oil breather | 27 | Flat key |

13 | Eccentric bearing | 28 | Motor shaft knots |

14 | Eccentric knots | 29 | Elastic ring |

15 | Motor gasket | 30 | Motor |

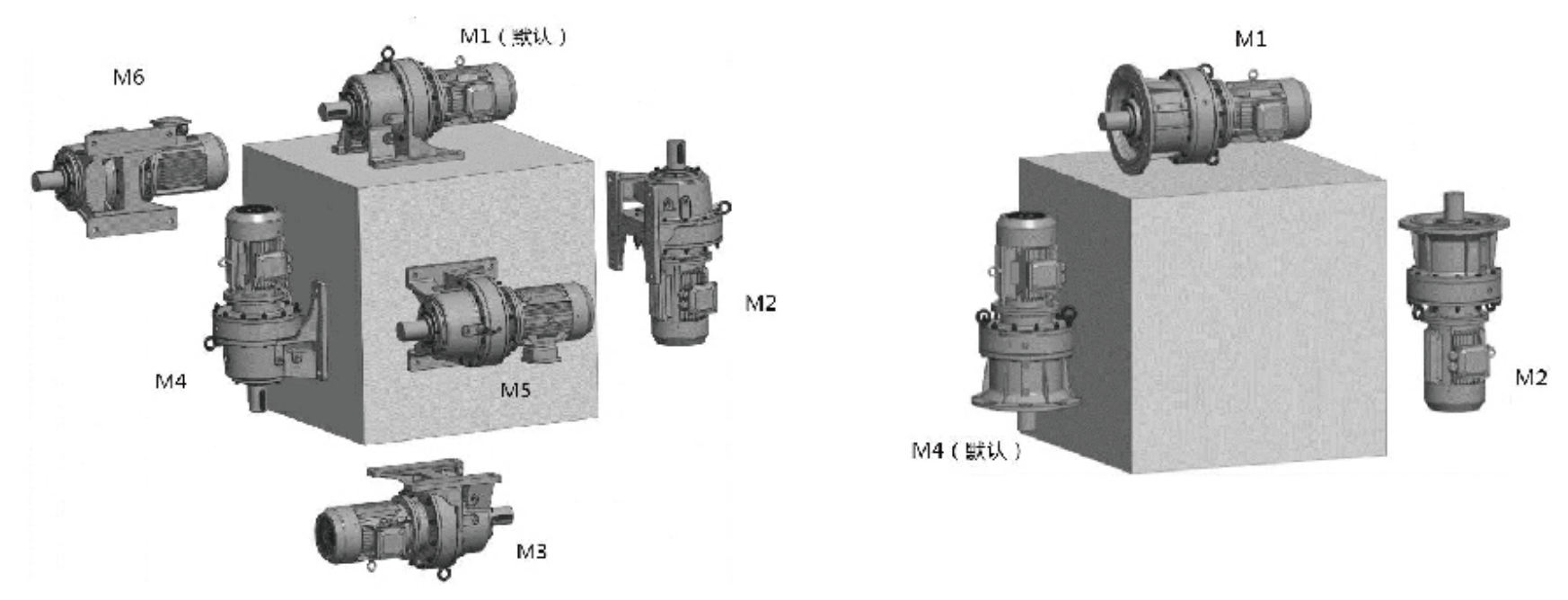

Mounting Arrangements Description

M1-horizontally mounted motor,unit base is at bottom.

M2-motor is vertically mounted downwards.

M3-horizontally mounted motor,unit base is top.

M4-motor is vertically mounted upwards.

M5-horizontally mounted motor,if placed on M1 position,left side of unit turns to bottom(view point:towards from motor side).

M6-horizontally mounted motor,if placed on M1 position,left side of unit turns to top(view point:towards from motor side).

Cycloidal reducer is a new type of transmission machinery which adopts planetary transmission principle with small tooth difference and cycloidal gear combination. It is widely used in driving and reducing devices in textile printing and dyeing, light industry food, metallurgical miners, petrochemical industry, lifting transportation and engineering machinery.

Feature:

● Smooth running,low noise gear tooth needle more engagement.

● Cycloidal tooth profile provides a high contact ratio to withstand overload shocks

● Compact size: single ratio available from 1/9 to 1/87, double stage up from 1/99 to 1/7569

● Ideal for dynamic applications: frequent start-stop-reversing duties suits for cyclo speed reducer since inertia is low

● Low maintenance costs ,high reliability, long service life, minimal maintenance compared to conventional gearboxes

● Grease Lubricated & Oil Lubricated Models Available

● Output Shaft Rotation Direction: Single Reduction: Clockwise Rotation; Double Reduction→ Counter Clockwise Rotation

● Cycloid reducer Capacity Range: 0.37kW ~ 11kW;

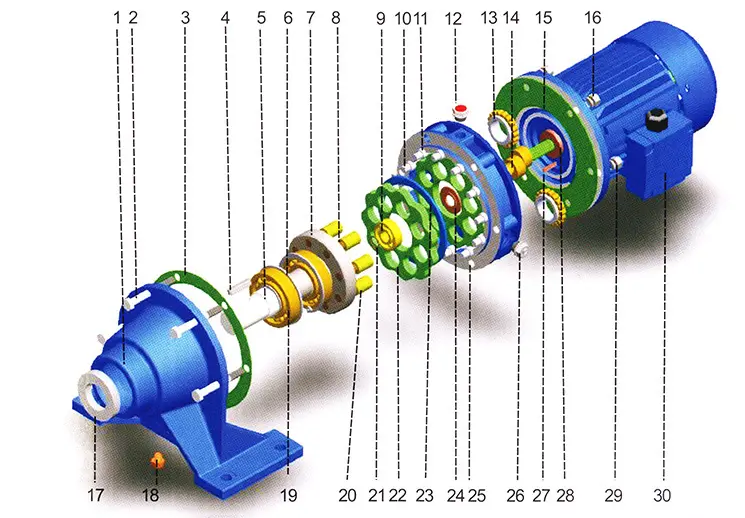

Details of the reducer

1 | Base | 16 | Nut |

2 | Hexagon bolt | 17 | Oil seal |

3 | Base gasket | 18 | Hexagon bolt |

4 | Flat key | 19 | Bearing |

5 | Circlip | 20 | Roller |

6 | Circlip | 21 | Clrclip |

7 | Output shaft | 22 | Cycloid gear |

8 | Pin | 23 | Patition ring |

9 | Bearing | 24 | Eccentric shaft knots |

10 | Gear pin | 25 | Pin wheel housing |

11 | Gear roller | 26 | Oil level plug |

12 | Oil breather | 27 | Flat key |

13 | Eccentric bearing | 28 | Motor shaft knots |

14 | Eccentric knots | 29 | Elastic ring |

15 | Motor gasket | 30 | Motor |

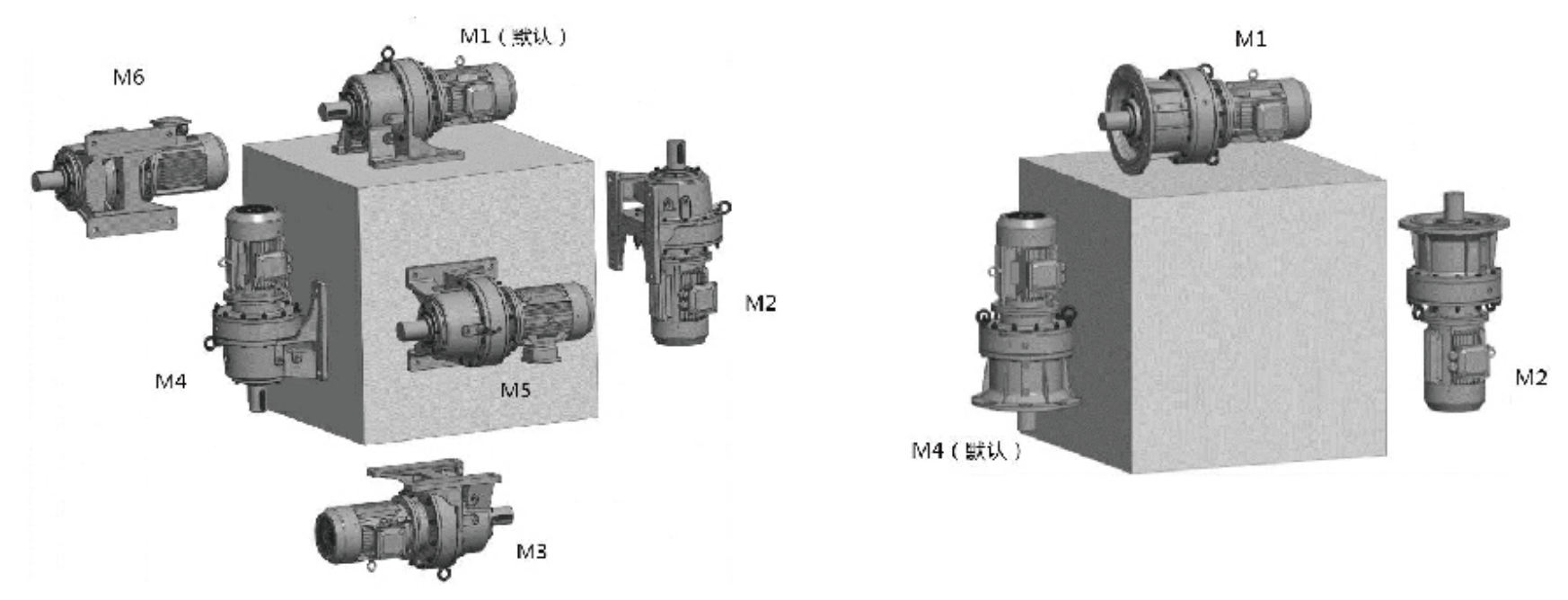

Mounting Arrangements Description

M1-horizontally mounted motor,unit base is at bottom.

M2-motor is vertically mounted downwards.

M3-horizontally mounted motor,unit base is top.

M4-motor is vertically mounted upwards.

M5-horizontally mounted motor,if placed on M1 position,left side of unit turns to bottom(view point:towards from motor side).

M6-horizontally mounted motor,if placed on M1 position,left side of unit turns to top(view point:towards from motor side).