Helical gears are essential components in modern industrial transmission systems, delivering smooth motion, stable torque, and low noise. Understanding their working principles helps users select the right helical geared motor for different industrial applications.

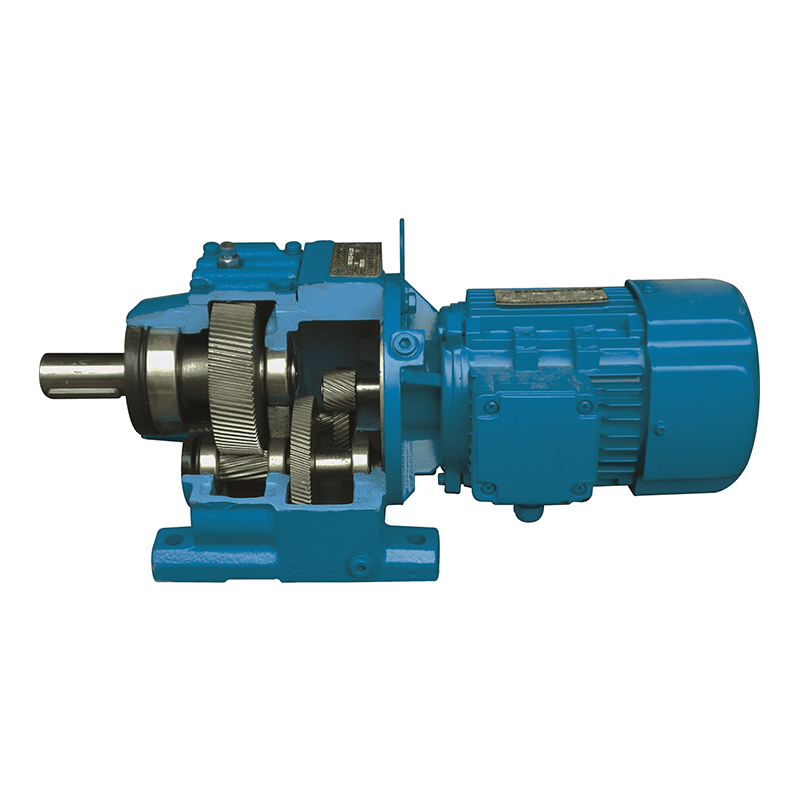

A helical gear is a cylindrical gear whose teeth are cut at an angle to the gear axis, forming a spiral-like pattern around the gear body. This angled tooth design changes how force is transferred during rotation and becomes the core mechanical reason why a helical geared motor delivers smoother and more stable performance. Instead of sudden engagement, the gear teeth connect progressively, which helps control load transfer inside the gearbox. From a structural point of view, helical gears differ clearly from spur gears. Spur gears rely on straight teeth and instant contact, while helical gears spread contact over time and space. This structural difference explains why helical geared motors are widely used in industrial systems that demand continuous operation and controlled motion. Key structural characteristics of helical gears include:

● Angled helicoid teeth that increase contact length and improve torque transmission

● A defined helix angle that determines overlap ratio and affects smoothness and axial load

● Wider effective tooth face, allowing load sharing across multiple teeth at the same time

● Gear materials and heat treatment options that support long service life in motor-driven systems Together, these elements form the internal structure that allows a helical geared motor to combine speed reduction, torque amplification, and mechanical stability in one compact unit.

Structural Feature | Description | Role in Helical Geared Motor |

Helical tooth angle | Teeth cut diagonally | Smoother engagement |

Tooth overlap | Multiple teeth in contact | Higher load capacity |

Gear face width | Increased contact area | Reduced wear |

The meshing behavior of helical gears is defined by gradual tooth engagement. Contact begins at one side of the gear face and moves steadily across as rotation continues. This process avoids the sudden impact seen in straight-tooth gears and spreads force more evenly inside the gearbox. This meshing pattern creates several practical advantages in a helical geared motor:

● Reduced shock loads during start-up and load changes

● Lower vibration levels across the entire speed range

● Quieter gearbox operation, especially at medium to high speeds

● More uniform stress distribution on gear teeth and bearings Because multiple teeth remain engaged at the same time, torque does not concentrate on a single contact point. Lubrication stays more consistent along the tooth surface, and internal components experience fewer abrupt force transitions. These characteristics make helical geared motors suitable for systems where smooth motion and mechanical balance matter more than simple cost savings.

Helical gears transmit power between parallel shafts by converting high motor speed into usable torque through controlled gear ratios. Inside a helical geared motor, the motor and gearbox work together as a single drive unit, simplifying installation while improving efficiency. As gear size and tooth count change, speed decreases and torque increases in a predictable way. This power transmission process offers several operational advantages:

● Smooth acceleration and deceleration without sudden torque spikes

● Consistent torque output for driving heavy or variable loads

● Reliable speed reduction for equipment that cannot run at motor RPM

● Stable long-term performance under continuous duty conditions Helical geared motors are commonly selected for industrial applications because they handle ongoing operation well. Heat generation stays controlled, mechanical stress spreads evenly, and the drive system maintains steady motion over long production cycles. These traits explain their widespread use in conveyors, processing equipment, and automated production lines where dependable power transfer is essential.

Gear size starts the conversation when engineers design a helical gear set. In metric systems, we describe tooth size using the module, while imperial systems rely on diametral pitch. They express the same idea in different units: how big each tooth is and how many teeth fit on a given diameter. In a helical geared motor, this choice directly shapes torque capacity, durability, and long-term stability. As the module increases, gear teeth become thicker and stronger. That change allows the gear to carry higher loads without excessive surface stress. However, larger teeth also mean a larger gearbox footprint, so designers must balance strength and space. Correct sizing ensures the geared motor runs smoothly under continuous duty rather than operating near its mechanical limits. Key considerations engineers evaluate during sizing include:

● Required output torque and expected load fluctuations over time

● Motor speed and target reduction ratio inside the geared motor

● Installation constraints such as housing size and shaft center distance

● Material selection and heat treatment level for the gear teeth These factors work together to define whether a helical geared motor feels robust and stable or undersized and stressed in daily operation.

Parameter | Metric System | Imperial System | Practical Impact |

Tooth size unit | Module | Diametral pitch | Determines load capacity |

Larger value | Bigger teeth | Fewer teeth per inch | Higher torque handling |

Design trade-off | Strength vs size | Strength vs compactness | Affects gearbox layout |

The helix angle describes how steeply the gear teeth wrap around the gear body. It plays a major mechanical role because it controls how smoothly the teeth engage and how much overlap exists during rotation. In a helical geared motor, a larger helix angle usually means quieter operation and better load sharing across multiple teeth. However, the angled tooth geometry also introduces axial forces. As the gears rotate, part of the transmitted load pushes along the shaft axis instead of staying purely radial. These forces increase as the helix angle grows, which means designers must plan for them rather than ignore them. Designers account for axial loads through several coordinated measures:

● Selecting an appropriate helix angle that balances smoothness and axial force level

● Using thrust bearings or angular contact bearings to absorb axial loads

● Designing rigid housings to keep shafts aligned under combined forces

● Matching bearing capacity to long-term operating conditions This integrated approach allows a helical geared motor to benefit from smooth meshing while maintaining bearing life and shaft stability during continuous industrial use.

Helix Angle Effect | Mechanical Outcome | Design Response |

Increased angle | Smoother tooth engagement | Reduced noise |

Increased angle | Higher axial force | Stronger bearing system |

Moderate angle | Balanced performance | Longer service life |

The pressure angle controls how force travels between meshing teeth. It defines the direction of contact force and determines how load spreads along the tooth surface. In a helical geared motor, this parameter influences efficiency, mechanical stiffness, and how smoothly torque transfers during operation. Even small adjustments can change stress patterns inside the gearbox. Most industrial helical gears use standardized pressure angles because they balance strength and smooth engagement. These values also align well with common bearing and housing designs used in geared motors. As a result, engineers can predict performance more accurately across different load conditions. From a design perspective, the pressure angle affects several interconnected behaviors:

● Tooth contact behavior, influencing how rigid or flexible the gear pair feels

● Load distribution along the tooth face, reducing localized stress peaks

● Sliding motion between teeth, which impacts friction and heat generation

● Overall durability of gears and bearings during continuous-duty operation When chosen correctly, the pressure angle helps a helical geared motor deliver stable torque while protecting internal components from uneven wear.

Tooth height defines how deeply gears engage and disengage during rotation. The addendum measures the tooth height above the pitch circle, while the dedendum measures the depth below it. Together, they form the total tooth height, which affects strength, alignment tolerance, and contact stability inside a helical geared motor. Backlash refers to the intentional clearance between mating teeth when no load is applied. This gap is essential for reliable operation. It allows lubricant to flow into the contact zone and prevents binding as gears expand due to heat. Without controlled backlash, gears may run hot, noisy, or wear unevenly. Carefully managed clearance supports long service life in several ways:

● Maintains a stable lubrication film during continuous rotation

● Absorbs minor alignment errors between shafts and bearings

● Reduces noise caused by overly tight tooth engagement

● Protects tooth surfaces from scuffing and premature fatigue Designers tune tooth height and backlash together so the geared motor remains smooth, quiet, and reliable across changing loads and temperatures.

Geometry Term | What It Describes | Why It Matters in a Helical Geared Motor |

Pressure angle | Direction of tooth contact force | Affects load distribution and efficiency |

Addendum | Tooth height above pitch circle | Controls engagement depth |

Dedendum | Tooth depth below pitch circle | Provides running clearance |

Backlash | Clearance between teeth | Supports lubrication and longevity |

Helical gears are known for their smooth and quiet behavior during operation. Their angled teeth do not collide suddenly. Instead, contact starts at one edge and moves gradually across the gear face. In a helical geared motor, this progressive engagement softens force transfer and avoids sharp mechanical impacts that often create noise. This gradual meshing matters a lot in automated factories and industrial plants. Equipment often runs close to workers, sensors, or control systems. Lower noise helps improve the working environment and supports stable signal detection in automated lines. Several design-related factors contribute to this low-noise behavior:

● Gradual force application reduces vibration at startup and during load changes

● Overlapping tooth contact avoids sudden torque spikes

● Continuous engagement stabilizes rotation at medium and high speeds

● Controlled sliding contact limits resonance inside the gearbox housing For manufacturers supplying industrial drive solutions, quiet operation becomes a performance feature rather than a comfort bonus.

Gear Feature | Effect During Operation | Resulting Benefit |

Angled teeth | Progressive contact | Reduced noise |

Tooth overlap | Smoother torque flow | Lower vibration |

Continuous meshing | Stable rotation | Improved system comfort |

One key advantage of helical gears is how they share load. Unlike straight-tooth gears, several teeth remain engaged at the same time. This design spreads force across a wider contact area. In a helical geared motor, load sharing allows compact gearboxes to transmit higher torque without overstressing individual teeth. This characteristic becomes critical when space is limited but output torque must remain high. Many industrial systems cannot afford large gearboxes, yet they demand stable torque delivery. Manufacturers like FSCOPartner rely on this property to design compact geared motors that still perform under heavy loads. Load sharing improves torque capability through multiple mechanisms:

● Reduced stress per tooth, lowering the risk of surface fatigue

● Even force distribution along the gear face

● Improved resistance to shock loads during start-stop cycles

● Better compatibility with high-reduction gear stages As a result, helical geared motors can deliver higher torque density while maintaining predictable mechanical behavior.

Load Behavior | Mechanical Impact | Practical Outcome |

Multiple teeth engaged | Shared contact stress | Higher allowable torque |

Wider contact zone | Lower peak pressure | Compact gearbox design |

Stable force transfer | Reduced shock sensitivity | Reliable industrial use |

Durability defines whether a gear system performs well only on paper or survives years of operation. Helical gears reduce tooth stress by spreading contact forces across time and surface area. In continuous-duty applications, this design helps the helical geared motor maintain consistent performance even under high speed and high torque. Reliability also comes from stable thermal and mechanical behavior. Smooth engagement reduces friction peaks, while balanced load paths protect bearings and shafts. These factors matter in industries where downtime leads directly to production loss. Helical gears support long service life in several demanding environments:

● Conveyor systems operating nonstop under varying loads

● Packaging machinery requiring smooth, repeatable motion

● Material handling equipment exposed to frequent starts and stops

● Automated production lines running at controlled high speeds Because stress stays distributed and motion remains stable, helical geared motors fit naturally into industrial systems designed for continuous, predictable operation.

The core difference between helical gears and spur gears lies in tooth geometry and force behavior. This difference strongly affects how a helical geared motor performs under real operating conditions. Key structural and functional distinctions include:

● Spur gears use straight teeth parallel to the shaft, while helical gears use angled teeth wrapped around the gear body

● Straight teeth engage almost instantly, creating abrupt force transfer

● Angled teeth engage progressively, spreading force across time and surface area

● Helical gears generate axial force along the shaft, spur gears do not

● Spur gears can be viewed as a special case of helical gears where the helix angle equals zero These differences explain why helical gears feel smoother and more refined in motion-critical systems.

As rotational speed increases, gear behavior becomes easier to notice. Spur gears tend to grow louder because tooth contact happens all at once. Helical gears reduce this effect by applying force gradually during meshing. In a helical geared motor, this leads to quieter operation and lower vibration. This performance gap matters in real applications such as automotive transmissions and industrial gearboxes. Reduced noise improves user experience and protects nearby equipment from vibration-related issues. Smooth rotation also supports higher operating speeds without sacrificing stability.

Operating Factor | Spur Gears | Helical Gears |

Tooth engagement | Sudden contact | Gradual contact |

Noise at high speed | Higher | Lower |

Vibration behavior | More pronounced | More stable |

Speed suitability | Low to medium | Medium to high |

Helical gears dominate applications where smooth motion and continuous duty matter more than simple structure. A helical geared motor fits naturally into these scenarios because it balances torque, noise control, and durability. Common applications include:

● Conveyors and elevators running for long production cycles

● Mixers and compressors requiring steady torque output

● Cutters and processing machines exposed to frequent load changes

● Food processing, textiles, plastics, and packaging industries Manufacturers often choose helical geared motors from Copartner Technology in these fields because they support compact layouts, low noise environments, and reliable long-term operation.

Helical gears use angled teeth to transmit power smoothly and quietly while sharing load across multiple contact points. These design principles directly affect efficiency, durability, and torque output in a helical geared motor. By understanding how helical gears function, users can better select reliable drive solutions from experienced manufacturers such as Copartner Technology Co., Ltd., ensuring stable performance in long-term industrial operation.