Views: 0 Author: Site Editor Publish Time: 2026-01-26 Origin: Site

Why do some machines run smoothly for years, while others struggle under load? The difference often starts with the drive system.

A helical geared motor combines controlled speed and high torque in one compact unit. It powers conveyors, packaging lines, and automated equipment every day.

In this article, you will learn what a helical geared motor is, how it works, and why industries rely on it for efficiency, low noise, and long-term reliability.

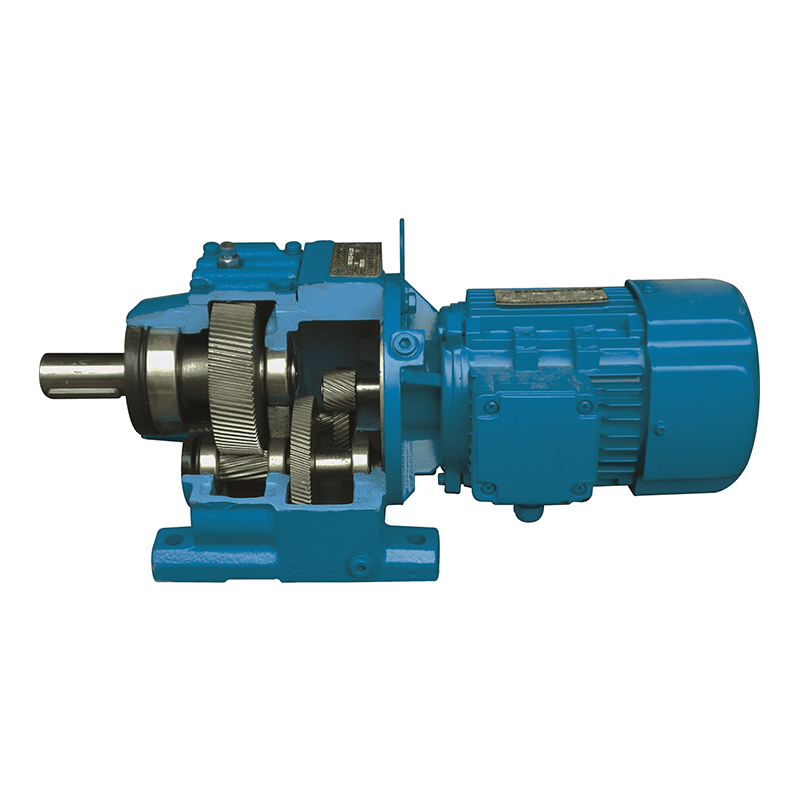

A helical geared motor is an integrated drive unit where an electric motor and a helical gearbox operate as a single system. The motor generates speed, and the gearbox converts that speed into usable torque through angled gear teeth. This integration removes the guesswork of matching separate components and delivers predictable performance under real industrial loads.

From a buyer’s perspective, it becomes relevant when machines must run smoothly for long hours. It helps control speed precisely, keeps torque stable, and reduces mechanical stress across the system. Many engineers choose it because it balances efficiency, durability, and compact installation without complex alignment work.

In practical projects, people usually turn to a helical geared motor when:

● They need controlled output speed to keep production consistent.

● They require high torque without sudden shocks during startup.

● They expect continuous-duty reliability, often in 24/7 operations.

● They want a compact, integrated drive to simplify installation and maintenance.

Instead of chasing peak speed, the focus stays on stability, smooth motion, and long service life.

The defining feature of a helical geared motor lies in the gear teeth. Unlike straight teeth, helical teeth are cut at an angle along the gear axis. As the gears rotate, contact begins gradually and spreads across the tooth surface. This overlapping engagement keeps motion smooth and distributes force more evenly.

The helix angle controls how this engagement behaves. A moderate angle allows several teeth to share the load at the same time, improving strength and durability. As the angle increases, smoothness improves, but axial thrust also increases. That thrust pushes along the shaft and must be managed carefully through bearing design and housing stiffness.

For customers, these fundamentals translate into real operating advantages:

● Starts and stops feel smoother, even under load.

● Vibration levels stay lower, protecting connected equipment.

● Gear wear slows down due to shared contact.

● Noise drops, which matters in enclosed or noise-sensitive environments.

Understanding this balance helps buyers see why helical designs outperform simpler gear types in continuous industrial use.

A helical geared motor is more than gears and a motor bolted together. Its service life depends on how each internal component handles load, heat, and axial forces. When reviewing a quotation, buyers should look beyond power ratings and pay attention to construction details.

The gearbox unit determines reduction ratio and torque capacity. Gear material, heat treatment, and machining accuracy directly influence efficiency and wear resistance. The motor unit must match the gearbox in duty cycle, otherwise thermal stress builds up quickly. Lubrication and cooling systems manage friction and temperature, especially during long operating cycles.

One area buyers often overlook is bearing design. Helical gears generate axial forces, so bearings must be selected to handle both radial and thrust loads. Asking about bearing type, load rating, and arrangement can prevent premature failures and vibration issues later.

Component | Primary Role | Impact on Reliability |

Gearbox | Speed reduction and torque multiplication | Controls efficiency and wear |

Motor | Supplies continuous input power | Affects thermal stability |

Bearings | Handle radial and axial forces | Prevent shaft and gear damage |

Lubrication | Reduces friction and heat | Extends service intervals |

Housing | Maintains alignment and rigidity | Limits vibration and noise |

A helical geared motor starts working the moment electrical power turns into motor rotation. The motor shaft spins at relatively high speed, then feeds that motion directly into the helical gearbox. Inside, angled gear teeth engage gradually instead of hitting all at once. This process slows rotation down while multiplying torque, then transfers stable power through the output shaft to drive the load.

What makes this process stand out is the way the teeth connect. Because contact builds progressively along the gear face, torque transfer stays smooth and controlled. Shock loads drop significantly, which protects shafts, couplings, and connected machinery. For systems running conveyors, mixers, or automated lines, this smooth transition helps maintain accuracy and mechanical balance.

In day-to-day operation, this working principle delivers clear advantages:

● Speed reduction happens steadily, not abruptly, even under changing loads.

● Torque increases without sharp mechanical stress.

● Power flow stays consistent, helping equipment run longer between maintenance cycles.

● Drivetrain components experience less fatigue over time.

When customers compare one helical geared motor to another, performance metrics matter more than theory. Efficiency often comes first. Well-designed helical systems typically operate around 90%–98% efficiency, depending on gear stages, lubrication quality, and operating load. For production lines running all day, small efficiency gains reduce energy costs and limit wasted heat.

Noise and vibration also influence buying decisions. Gradual tooth engagement lowers vibration levels and keeps sound output minimal. That makes helical geared motors a common choice in packaging, food processing, and precision environments where noise control supports both product quality and operator comfort.

Heat management ties everything together. Friction always creates heat, especially at high speeds or heavy loads. Proper lubrication and cooling help control temperature, protect bearings, and stabilize efficiency. In demanding setups, buyers often pay close attention to oil type, cooling method, and thermal limits before finalizing a specification.

Performance Factor | What It Influences | Why Customers Care |

Efficiency | Energy use and heat generation | Lower operating costs |

Noise & vibration | Machine stability and comfort | Precision and workplace safety |

Heat control | Component lifespan | Reliability in 24/7 operation |

When buyers look at a helical geared motor, the first distinction usually comes from its mechanical layout. Different configurations exist because machines face different space limits, load directions, and installation constraints. The internal working principle stays the same, but the way power is delivered changes how easily the motor fits into a system.

Inline helical geared motors place the motor and gearbox on the same axis. This design stays compact and efficient, making it common in conveyors, pumps, and general automation lines. Engineers like it because alignment feels straightforward and power transfer stays clean. Parallel shaft helical geared motors move the output shaft parallel to the motor shaft. This creates more flexibility during installation and allows higher torque handling, which suits heavier-duty equipment and longer conveyors. Helical bevel geared motors combine helical and bevel stages to achieve right-angle transmission. They fit machines where layout forces a 90-degree turn, such as mixers, crushers, and rotary systems.

Mounting style often decides how smoothly a helical geared motor integrates into existing equipment. Many buyers focus on power and ratio, then realize too late that mounting details slow down installation or maintenance. Choosing the right interface early saves time later.

Common mounting styles include foot-mounted, flange-mounted, and shaft-mounted designs. Foot mounts support stable base installation, while flange mounts simplify direct connection to machine frames. Shaft-mounted versions reduce alignment work and work well where space remains tight. These options let engineers adapt the same motor concept to many layouts without redesigning the whole machine.

Output and interface details also affect serviceability. Solid shaft outputs remain popular because they allow easy coupling and replacement. Motor-mount approaches, especially standardized mounts, make motor servicing faster and reduce downtime. When buyers compare quotations, checking these details often reveals which solution fits daily operation better, not just technical specs.

The reason a helical geared motor appears across so many industries comes down to return on investment. It delivers stable torque, quiet operation, and long service life in both light and heavy environments. That balance keeps operating costs predictable while protecting connected machinery.

In standard industrial settings, these motors power conveyors, material handling systems, packaging lines, textile and printing machines, mixers, intralogistics systems, filling and labeling equipment, and automated production cells. In heavier environments, they handle mining, cement, steel, and other high-torque machinery. They also perform reliably in escalators, HVAC systems, and agricultural equipment, where uptime matters more than speed.

Application Area | Typical Load Profile | Why Helical Geared Motors Fit |

Conveyors & handling | Continuous, steady load | Smooth torque and low vibration |

Packaging & printing | Precision, low noise | Stable speed and quiet operation |

Mixers & crushers | High torque, shock load | Strong load sharing and durability |

Mining & cement | Heavy-duty, long runtime | High torque and thermal stability |

HVAC & escalators | Reliability-focused | Continuous-duty performance |

Choosing a helical geared motor starts long before looking at a model number. Engineers and buyers usually begin by mapping real operating conditions, not catalog values. Torque demand comes first, since it defines gearbox size and gear strength. Speed ratio follows, because it sets how the motor’s input speed becomes usable output motion. Load type matters just as much. Constant loads behave very differently from variable or shock loads, and the drive must handle all of them without stress.

Mounting arrangement and environment also shape the decision. Limited space may push toward compact layouts, while dusty, humid, or high-temperature environments demand stronger sealing and thermal stability. Energy efficiency often feels secondary at first, yet it becomes critical on continuous lines. When a motor runs day and night, even small efficiency gains translate into real savings over years.

In practice, teams often walk through questions like these:

● How much torque does the application truly need during peak load?

● What output speed keeps the process stable and productive?

● Does the load stay constant, or does it fluctuate or shock the system?

● Which mounting style fits the machine frame without redesign?

● How important is energy efficiency over long operating cycles?

Manufacturers such as Copartner design their helical geared motor ranges around these exact questions, offering flexible ratios, mounting options, and duty-rated designs that support both performance and long-term cost control.

Selection Factor | What to Evaluate | Why It Affects Long-Term Value |

Torque & speed | Peak and continuous demand | Prevents overload and inefficiency |

Load type | Constant, variable, shock | Guides gearbox and bearing design |

Mounting | Foot, flange, shaft | Simplifies integration |

Environment | Dust, heat, humidity | Protects service life |

Efficiency | Rated vs real usage | Lowers lifetime energy cost |

Reliability in a helical geared motor comes from design choices, not quick fixes. One key requirement is managing axial thrust. Helical gears naturally create axial forces along the shaft. Well-designed systems handle this through proper thrust bearings and rigid housings. Regular bearing checks then become part of planned maintenance, not emergency repair.

Lubrication strategy plays an equally important role. Oil bath systems suit many standard applications, while grease or forced lubrication supports higher speeds or heavier loads. Temperature monitoring adds another layer of protection. Rising heat often signals overload, lubrication breakdown, or alignment issues. Catching it early keeps both gearbox and motor healthy.

From a user’s perspective, these reliability measures translate into predictable operation:

● Bearings remain stable under long-term axial load.

● Gears stay protected by consistent lubrication films.

● Heat stays controlled, preserving efficiency and insulation life.

● Maintenance shifts from reactive to planned intervals.

Modern factories treat a helical geared motor as a long-term asset, not a consumable part. That mindset shapes the maintenance plan from day one. Preventive care focuses on keeping friction, heat, and alignment under control. Lubrication checks ensure gears stay protected during continuous operation. Bearing and shaft inspections help catch wear early, before vibration spreads through the drivetrain. Regular cleaning also matters, especially in dusty or humid environments, where buildup can trap heat and shorten service life.

A solid maintenance routine usually includes:

● Scheduled lubrication checks to keep oil or grease in optimal condition.

● Bearing and shaft inspection to manage radial and axial loads.

● Cleaning of housing and cooling surfaces to stabilize temperature.

● Planned service intervals instead of reactive shutdowns.

Beyond maintenance, factories now expect drives to be automation-ready. Buyers often ask for encoder feedback to monitor speed and position in real time. Brake systems support precise stopping or holding loads safely. Integration with variable speed drives and PLCs allows the motor to adapt to changing process demands. These features turn a standard helical geared motor into a smart component, capable of supporting condition monitoring and predictive maintenance strategies.

Factory Expectation | Feature Requested | Operational Benefit |

Reduced downtime | Preventive maintenance access | Longer service intervals |

Smart control | Encoder feedback | Accurate speed and position data |

Safe operation | Brake systems | Controlled stopping and holding |

Flexible automation | VFD / PLC integration | Process optimization |

Within this landscape, Copartner Technology (FSCOPartner) positions itself as a supplier focused on practical industrial performance. Their helical geared motor solutions emphasize stable speed regulation, high torque output, and compact mechanical design. These characteristics align well with factories seeking reliable drives that fit easily into automated systems and continuous-duty environments.

Copartner also offers a broader geared motor portfolio, which helps buyers compare options within one supplier instead of mixing brands. This range includes helical geared motors, bevel geared motors, worm gear motors, cycloidal pinwheel reducers, and parallel shaft geared motors. Having multiple configurations under one roof simplifies selection and standardization across production lines.

Credibility comes from design focus and compliance. Copartner highlights IE2 and IE3 efficiency targets, supporting energy-conscious operations. Quality and market compliance references such as ISO9001 and CE further reinforce suitability for global industrial use. For buyers planning long-term automation and stable operation, this combination of efficiency focus, portfolio depth, and compliance creates a clear fit for modern factory expectations.

This article explains what a helical geared motor is and how it works in real machines. It covers torque output, efficiency, noise control, and long-term reliability. Copartner Technology provides helical geared motor solutions focused on compact design, stable speed control, and high torque for continuous industrial operation.

A: A helical geared motor combines an electric motor and helical gearbox to deliver controlled speed and high torque efficiently.

A: The motor drives helical gears that gradually reduce speed and increase torque through smooth tooth engagement.

A: A helical geared motor offers higher efficiency, lower noise, and better durability for continuous-duty applications.

A: A helical geared motor is widely used in conveyors, packaging lines, material handling, and industrial automation systems.

A: Regular lubrication, bearing inspection, and temperature monitoring help a helical geared motor run reliably long term.